Special machine construction / PINFLOW deburring technology

The deburring system for your requirements:

thorough • quick • economical

The deburring of workpieces is gaining in importance. In recent years, the performance of metal cutting processes has been signi ficantly increased. At the

same time, however, deburring is often still performed using the same method as decades ago. The deburring operation in parti cul ar places high demands on quality and process reliability in order to be able to manufacture cost effectively and with high quality in today’s highly o rganized production structures and increasingly complex workpieces. Here, the PINFLOW process is particularly suitable as an innovative alternative to other pr ocesses.

The PINFLOW principle

The workpieces to be deburred are clamped in a part specific fixture located on the workplate in the machining area of the machi ne. The work plate, together with the fixture and the workpieces, is set into horizontal vibrations . The fixture, which is designed as a container, is filled with the deburring medium. The vibrations generate a relative movement between the workpiece and the deburring medium.

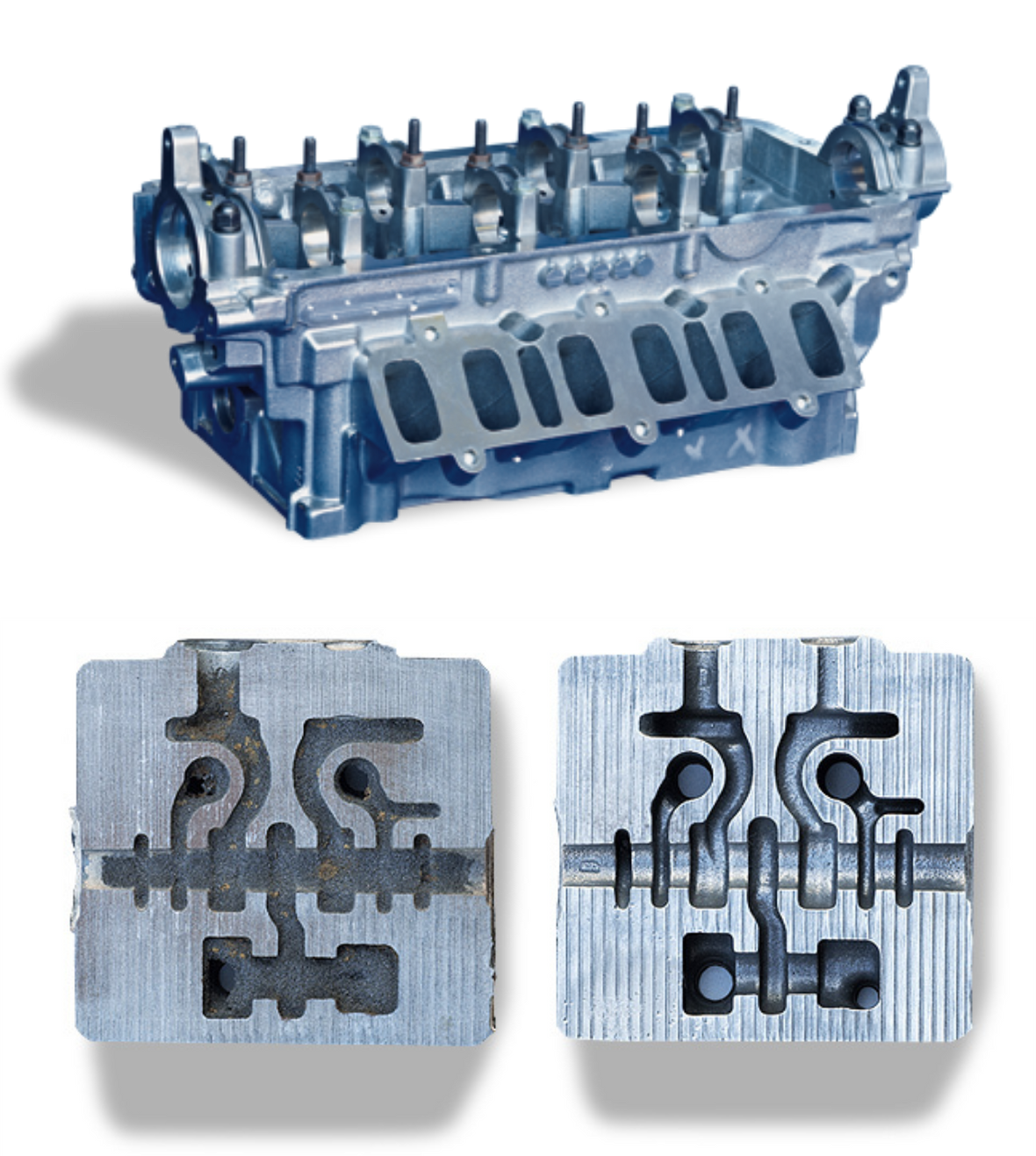

The deburring medium usually consists of small steel balls that not only work the outside of the workpiece during the machining process, but also penetrate into hard to reach parts inside the workpiece

The PINFLOW system can e.g. B. can be used wherever simple and complex workpieces are deburred inside and outside, where molding sand residues have to be removed or the surface has to be smoothed. The PINFLOW system is ideal for integration into existing production structures. Production islands in particular can be optimally supplemented by the PINFLOW system as a decentralized deburring system. The connection to cutting machines such as machining centers or lathes is very easy, regardless of whether the loading is done by hand or by an automatic loading system. The PINFLOW system can be used in both precision engineering production facilities and foundries.

Here you can see how the base plates and workpieces can be loaded and unloaded fully automatically into and out of the PINFLOW with the help of a KUKA robot.

2K Maschinenbau GmbH

a company of the 2K Group

Navigation

Service

Legal